Soft Pneumatic Grippers: A Gentle Solution for Handling Sensitive Electronics

Electronics manufacturing demands precision. From delicate circuit boards to tiny components, even the slightest damage during handling can lead to costly defects, product failures, or safety issues. Traditional robotic grippers, which rely on rigid mechanical fingers, can be too harsh or inflexible for these sensitive tasks.

Enter a new innovation: soft pneumatic grippers – inspired by nature and designed to handle delicate objects with a gentle, adaptive touch.

What Are Soft Pneumatic Grippers?

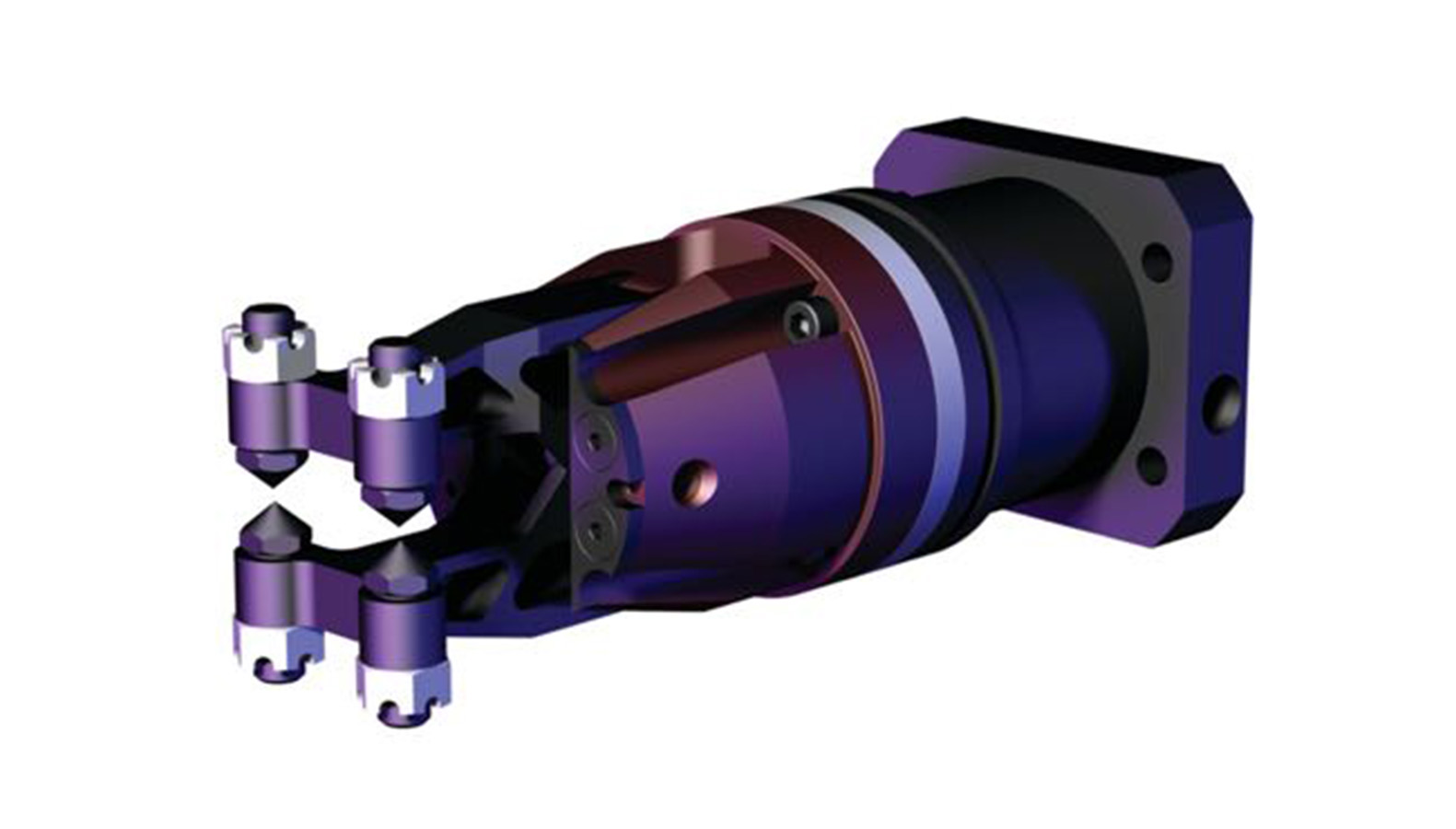

Instead of hard claws or mechanical fingers, soft pneumatic grippers use flexible, air-powered tentacle-like structures made from soft materials. When air is pumped into them, these “tentacles” curl and wrap around objects – much like an octopus gently grasping its surroundings.

Because the gripper conforms naturally to the shape of the object, it can securely hold items of various sizes and shapes without exerting damaging pressure.

Why They’re Game-Changing for Electronics Manufacturing

1. Gentle Handling of Fragile Components

Printed circuit boards (PCBs), microchips, sensors, and connectors are easily damaged by mechanical stress. Soft pneumatic grippers reduce contact pressure and spread the force evenly, minimising the risk of cracks, scratches, or misalignment.

2. Adaptable to Different Shapes and Sizes

Electronics production involves handling components with diverse geometries. Unlike traditional grippers that need to be reprogrammed or swapped out, soft grippers automatically conform to each item’s shape – improving flexibility and efficiency.

3. Reduced Downtime and Rework

Damage during handling is a major source of production delays and rework. With their gentle grip, pneumatic tentacle grippers cut down on rejects and quality issues, helping production lines run more smoothly.

4. Easier Automation Integration

These grippers rely on simple pneumatic control, making them relatively easy to integrate into existing automation systems – especially for manufacturers already using pneumatic technologies.

Real-World Applications in Electronics

- Pick-and-place of small components during PCB assembly

- Safe handling of finished circuit boards for inspection and testing

- Transporting sensors, wafers, and microdevices between workstations

- Automated packaging of fragile electronic products

A Natural Next Step in Automation

Soft pneumatic grippers combine the reliability of automation with the delicacy of human touch. For electronics manufacturers, this means safer handling, fewer defects, and more efficient production – all without major changes to existing systems.

We help manufacturers integrate advanced pneumatic automation solutions like these into their operations. Whether you’re handling fragile components or looking to improve product quality, our team can guide you in choosing the right solution for your needs. Contact our Product Specialists at sales@processpneumatics.com to learn how soft pneumatic grippers can improve your electronics manufacturing process!