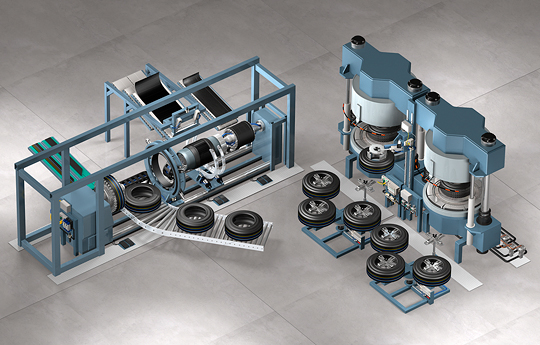

Tire Manufacturing

As global tire manufacturers cope with consolidation, rising raw material costs, and mounting competition, they face the absolute necessity of increasing production rates while decreasing costs. So they seek superior technology to satisfy many application requirements in an ever-more-automated environment.

For decades, both tiremakers and the OEMs that supply them have trusted ASCO Numatics to provide highly reliable, robust products that exceed the demands of their applications. With a broad range of air preparation and filtration products — from advanced G3 fieldbus electronic valve manifolds to proportional and process control valve technology — ASCO Numatics provides solutions.

In tire building, our directional control valves provide reliable, repeatable performance, cycle after cycle — while our patented Numatics G3 fieldbus electronics with graphic display offer the industry easy commissioning, visual status, and diagnostics. On the curing press, our steam valves furnish superior durability that stands up to the tire industry’s challenging conditions; our unique proportional valves can be easily tuned on site or preset at our factory to your exact requirements, saving weeks of development and startup time. And in the uniformity machine on the finishing process, our ISO and NFPA actuators deliver the precise linear motion and positional accuracy demanded for transfers. Depend on us in every part of the tire plant, including:

• Mixing Equipment

• Bead Building Machines

• Wire Calendars

• Extruders

• Fabric Calendars

• Bias cutters

• Tire Building Machines

• Curing Presses

• Inspection Machines

• Label Applicators

ASCO Numatics provides the industry’s most complete range of innovative, high-precision, ultra-reliable products for vehicle tire manufacturing. Our fluid automation solutions help tire manufacturers boost throughput, cut downtime, and ensure quality products in every part of the tiremaking plant.